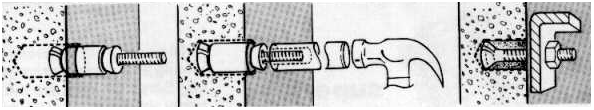

Expansion Bolts

1. Drill hole in masonry. Place head of bolt into hole first.

2. Drive on setting tool with hammer, one or two light taps first to make sure anchor is at bottom of hole - then several hard blows until lead is firmly packed.

3. Remove setting tool, place work to be installed over bolt, and screw nut on to bolt. Note how lead has been forced into every crevice to hold the bolt firmly.

Expanded Installation Instructions

1. Drill the proper size and depth hole.

For the ¼” anchor use a ½” drill, and for the 3/8” anchor use a 5/8” drill. The best indicator that the holes are too large is insufficient holding strength of the bolt. This can usually be detected earliest when the bolt moves forward by more than a fraction of an inch (1/4” max) during tightening

From previous problematic installations we have seen oversized holes occur because of

A) Too large of a drill

B) Rebar being hit while drilling.

C) Extremely hard concrete or concrete with large aggregate causing excessive movement of the drill when it is being held manually instead of with a fixture.

2. Make sure the anchor is at the bottom of the drilled hole before beginning installation.

The lead sleeve and washer should be entirely inside of the drilled hole before you begin to set the anchor. Gently tap the anchor until it is at the bottom of the drilled hole before you begin to compact the lead. Insufficient hole depth and poor cleaning of the hole are potential causes of the lead sleeve not fitting entirely inside of the drilled hole.

3. Compact the lead completely.

Two or three solid blows using a heavy hammer should be sufficient. Experienced installers can feel and hear the difference in striking the anchor once the lead is completely compacted. “A taper” setting tools are available for use with hammer drills to set the anchors.

4. Tighten the anchors firmly.

Proper tightening of the anchors is extremely important for two reasons;

First, if the anchor is properly installed then the bolt should not move forward more than one quarter of an inch (1/4”) during tightening. Ideally the forward motion of the bolt during tightening should be almost imperceptible. Excess forward motion of the bolt is one of the most obvious signs of an installation problem. The head of the bolt should remain near the bottom of the drilled hole after the fixture is installed and tightened down. If it appears that too much of the bolt is above the fixture after installation then the anchors should be tested.

Secondly, with insufficient tightening the anchor has to hold a dynamic load rather than a static load. A fixture in motion places a much larger force upon the anchors.

The anchors are designed to hold until the breaking point of the bolt. You only have to be afraid of over-tightening when you are approaching the breaking point of the bolt. In the absence of a torque wrench tighten the anchors extremely well, but do not go to a point where you might break the bolt.

The exact amount of torque to use for tightening, or the preload, will depend on the requirements of the fixture being held. Ideally a torque wrench should be used to ensure proper preload.

5. Other problems to watch for:

Weak, friable concrete or insufficient aggregate at the surface. This is sometimes earliest detected when the concrete breaks at the surface during drilling. Another indicator is excessive dust in the drilled holes. Once a hole is blown clean new dust should not enter from the walls of the hole.

If a poor concrete surface is suspected then testing should be done to determine if the holes need to be drilled deeper utilizing longer anchors.